Product Comparison

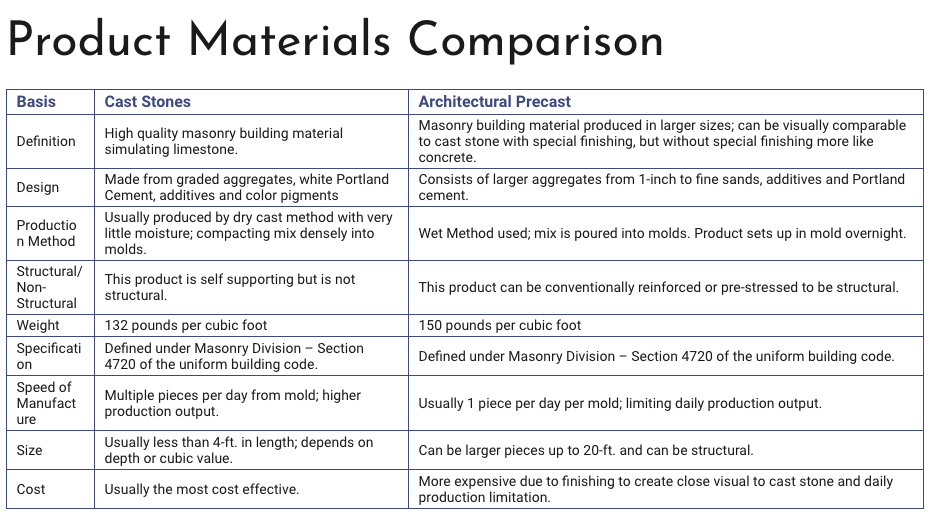

Product Materials Comparison

| Basis | Cast Stones | Architectural Precast |

|---|---|---|

| Definition | High quality masonry building material simulating limestone. | Masonry building material produced in larger sizes; can be visually comparable to cast stone with special finishing, but without special finishing more like concrete. |

| Design | Made from graded aggregates, white Portland Cement, additives and color pigments | Consists of larger aggregates from 1-inch to fine sands, additives and Portland cement. |

| Production Method | Usually produced by dry cast method with very little moisture; compacting mix densely into molds. | Wet Method used; mix is poured into molds. Product sets up in mold overnight. |

| Structural/Non-Structural | This product is self supporting but is not structural. | This product can be conventionally reinforced or pre-stressed to be structural. |

| Weight | 132 pounds per cubic foot | 150 pounds per cubic foot |

| Specification | Defined under Masonry Division – Section 4720 of the uniform building code. | Defined under Masonry Division – Section 4720 of the uniform building code. |

| Speed of Manufacture | Multiple pieces per day from mold; higher production output. | Usually 1 piece per day per mold; limiting daily production output. |

| Size | Usually less than 4-ft. in length; depends on depth or cubic value. | Can be larger pieces up to 20-ft. and can be structural. |

| Cost | Usually the most cost effective. | More expensive due to finishing to create close visual to cast stone and daily production limitation. |

Product Characteristics

| Basis | Cast Stones | Architectural Precast |

|---|---|---|

| Definition | High quality masonry building material simulating limestone. | Masonry building material produced in larger sizes; can be visually comparable to cast stone with special finishing, but without special finishing more like concrete. |

| Design | Made from graded aggregates, white Portland Cement, additives and color pigments | Consists of larger aggregates from 1-inch to fine sands, additives and Portland cement. |

| Production Method | Usually produced by dry cast method with very little moisture; compacting mix densely into molds. | Wet Method used; mix is poured into molds. Product sets up in mold overnight. |

| Structural/Non-Structural | This product is self supporting but is not structural. | This product can be conventionally reinforced or pre-stressed to be structural. |

| Weight | 132 pounds per cubic foot | 150 pounds per cubic foot |

| Specification | Defined under Masonry Division – Section 4720 of the uniform building code. | Defined under Masonry Division – Section 4720 of the uniform building code. |

| Speed of Manufacture | Multiple pieces per day from mold; higher production output. | Usually 1 piece per day per mold; limiting daily production output. |

| Size | Usually less than 4-ft. in length; depends on depth or cubic value. | Can be larger pieces up to 20-ft. and can be structural. |

| Cost | Usually the most cost effective. | More expensive due to finishing to create close visual to cast stone and daily production limitation. |

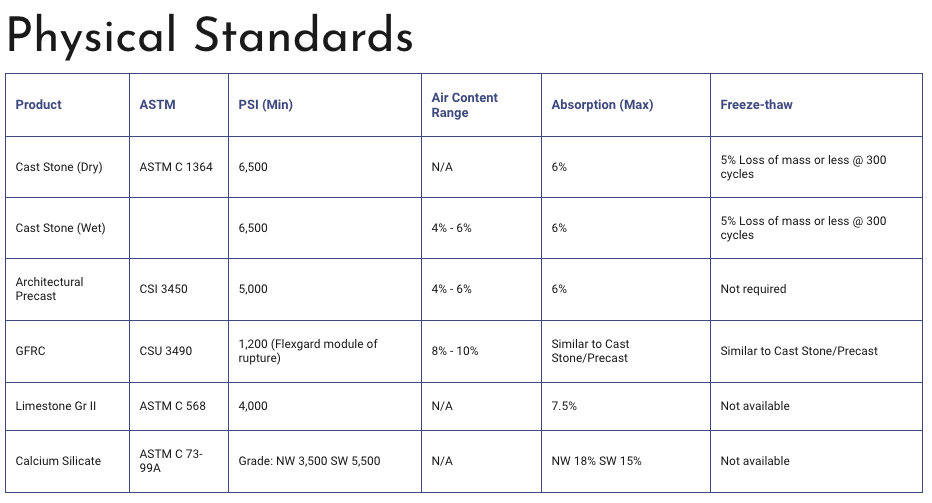

Physical Standards

| Product | ASTM | PSI (Min) | Air Content Range | Absorption (Max) | Freeze-thaw |

|---|---|---|---|---|---|

| Cast Stone (Dry) | ASTM C 1364 | 6,500 | N/A | 6% | 5% Loss of mass or less @ 300 cycles |

| Cast Stone (Wet) | 6,500 | 4% - 6% | 6% | 5% Loss of mass or less @ 300 cycles | |

| Architectural Precast | CSI 3450 | 5,000 | 4% - 6% | 6% | Not required |

| GFRC | CSU 3490 | 1,200 (Flexgard module of rupture) | 8% - 10% | Similar to Cast Stone/Precast | Similar to Cast Stone/Precast |

| Limestone Gr II | ASTM C 568 | 4,000 | N/A | 7.5% | Not available |

| Calcium Silicate | ASTM C 73-99A | Grade: NW 3,500 SW 5,500 | N/A | NW 18% SW 15% | Not available |